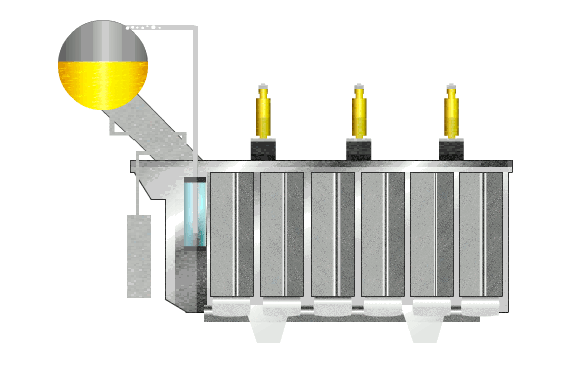

Receiving of transformer oil→sampling and

inspection→filtering of transformer oil→vacuum treatment and

oil filling→oil hot oil cycle→tightness test and static storage

For the reception of transformer oil, the

transformer oil should meet the following standards:

(a) The appearance is transparent, without

suspended solids or mechanical impurities;

(b) Acid value after oxidation

<0.2mgKOH/g;

(c) Sediments after oxidation <0.05%.

(d) When the temperature is about 40

degrees, the dynamic viscosity is less than 13mm2/s

(e) Water content 220kV<15ppm; 500kV<10ppm

(f) Acid value<0.03mgKOH/g

(g) Ignition point>140℃;

(h) Flash point (closed)>140°C

(i) Gas content <1%

(j) Dielectric strength: 220kVZ40kV/2.5mm;

500kV260kV/2.5mm

(k) breakdown voltage>35kV

(l) Does not contain polychlorinated

biphenyls (PCB) and corrosive sulfur dielectric loss tangent tg6<5% (at a temperature of 90°C)

(m) Storage requirements for transformer

oil: Transformer oil should be stored in sealed and clean special oil tanks or containers.

When draining oil from the oil tank,

connect the oil pipeline, the high-vacuum oil purifying machine will heat the

oil temperature by self-circulation, the oil purifying machine will clean

itself, use the oil purifying machine to clean the hot oil and flush the oil

pipeline, if the inside of the oil storage tank has been scrubbed clean, no

need for a transformer Oil flushing, the flushing oil should be stored

separately and marked well; after the transformer oil arriving at the site is

introduced into the oil tank with an oil purifying machine, a high vacuum transformer

oil filtration machine is used to filter the transformer oil. In order to

improve the oil purifying machine effect, the oil storage tank should be

filtered with Inverted tank oil purifying method, that is, all the transformer

oil in one oil storage tank is filtered to another oil storage tank through a

high vacuum oil purifying machine, and then filtered from another oil storage

tank to the original oil storage tank, such as on-site storage If there are few

oil tanks, the self-circulation of the oil storage tank can be used, but the

relevant sealing must be done well, the outlet temperature of the oil purifying

machine should not be lower than 50°C, and the filtered transformer oil should

be tested for oil samples to judge whether the purification treatment of the

transformer oil is qualified , the oil sample can be sampled from the oil drain

of the sampling valve of the oil purifying machine unit;

Precautions for transformer oil filtration:

1) Fences should be set up in the

transformer construction area and warning signs should be hung;

2) Fireworks are strictly prohibited in the

transformer construction area, and sodium carbonate dry powder fire

extinguishers are equipped on site;

3) Before filtering oil, it is necessary to

check whether all equipment and components are reliably grounded;

4) When the oil pipe is connected, it must

be tied firmly to prevent oil leakage and leakage;

5) During the period of transformer oil

filtration, the on-duty personnel should patrol and check the status of

equipment and oil system, and make records;

6) When accepting incoming oil, calculate

the total amount of incoming oil, distribute the flushing oil, install it, try

to avoid wasting oil, and ensure that the transformer is filled with oil at one

time;

7) During the process of transformer oil

filtration, the manhole door of the oil storage tank should be sealed with

plastic cloth, and the bottom of the added moisture absorber should be filled

with enough oil according to the scale line

8) The minimum oil temperature at the

outlet of the oil purifying machine is 50°C, and the maximum should not exceed

70°C;

9) Observe the oil quality of the vacuum

pump of the oil purifying machine unit, and replace the vacuum pump oil in

time;

10) Pay attention to observe the oil level

in the oil accumulation window of the oil purifying machine unit, and stop the

machine in time to drain the oil;

11) Pay attention to observe the outlet

pressure gauge of the filter screen of the oil purifying machine unit, and

replace the filter screen in time;

12) When the oil pipe is not in use, it

should be sealed tightly with plastic cloth immediately to prevent moisture and

impurities from entering the pipe;

13) After filtering the oil in the oil

storage tank, seal the outlets of the oil tank tightly with plastic cloth in

time;

14) Before the heater of the oil purifying

machine unit is put into operation, it must be confirmed that the oil level of

the oil purifying machine unit is normal. Before the oil purifying machine unit

is shut down, the heater should be turned off to prevent the heater from

burning in vain and damage to the equipment.

The preconditions for vacuum treatment and

oil injection work are as follows: the transformer oil is dehydrated, degassed

and filtered through the vacuum oil purifying machine, and the oil quality

meets the requirements.

In the process of vacuuming the transformer,

check for leakage at any time. In order to hear the sound of leakage, you can

stop the vacuum pump if necessary, find the leakage, and repair it in time.

When the vacuum degree is <50Pa, the time to maintain the vacuum degree is not less than The exposure time of the body in the air should not be less than 24 hours; oil filling should be started under the condition that the transformer has no leakage;

After the vacuuming time reaches the

requirement, open the valve and inject oil through the vacuum oil purifying

machine. During oil injection, the average oil temperature at the outlet of the

vacuum oil purifying machine should be controlled at 45°C-55°C. During the

entire vacuum oiling process, record the vacuum degree every hour, the oiling

start time, stop time, the problems that occurred and the treatment process

should be recorded in detail; If the oil level changes, after filling the oil,

close the oil filling valve and dismantle the oil filling device, use all

components, accessories of the transformer and all the air release plugs of the

pipeline to release air, if there is oil overflow, tighten the air release plug

immediately, and wipe off the overflowing oil. The rubber pad of the vent plug

is relatively small, so moderate force should be used to seal well without

damaging the rubber pad.

In order to eliminate dampness on the

insulating surface of the body during installation, hot oil circulation should

be carried out after vacuum oil filling of transformers of 330kV and above.

Main transformer hot oil circulation Before hot oil circulation, the oil pipe

should be vacuumed to clean the air in the oil pipe; the oil in the cooler and

the oil in the main body of the oil tank should undergo hot oil circulation at

the same time; the hot oil circulation should be carried out through a vacuum oil

purifying machine, and the whole The vacuum degree of the circulation system

(including the transformer) should be kept at <130Pa during the whole hot oil circulation process, and the transformer should not be filled with oil, and the oil surface should be 100mm-200mm away from the top cover; the oil temperature in the oil tank should be maintained at 60°C-70°C, the cycle

time must meet the following conditions before it can be terminated: the

duration of hot oil circulation should not be less than 72 hours; The oil

quality of the transformer oil after the oil circulation should meet the

standard requirements when the transformer oil is received.

Dears,

Through the above description, perhaps you already have a certain understanding of PURETECH's Transformer Oil Purifiers/Transformer Oil Filtration Machine/Transformer Oil Purifying Machine/Transformer Oil Treatment Plant. If you have determined the model, flow, power supply, configuration, etc. you need, please inform our sales team. We will prepare a quotation and detailed technical information for you as soon as possible for your further reference.

Web: www.cqpuretech.com

Email: sales@cqpuretech.com | cqpuretech@gmail.com

Tel: +86 17815389416 (WhatsApp)

Name: PURETECH

Mobile:+86 17815389416

Tel:+86 17815389416

Whatsapp:+8617815389416

Email:sales@cqpuretech.com

Add:1 Xinmao Road, Beibei district, Chongqing, China