How To Purify Used Transformer Oil

Insulating oil is a kind of lubricating oil. It is usually produced by adding deeply refined lubricating base oil with antioxidants, mainly used as the dielectric of electrical equipment. The main properties of electrical insulating oil are Low Temperature Performance, Oxidation Stability and Dielectric Loss.

-

Low temperature performance refers to the necessary fluidity for insulation oil to automatically convect, extract heat and cut off the arc current instantly in electrical equipment under low temperature conditions. Generally it requires the insulating oil with low pour point and low viscosity at low temperature.

-

In electrical equipment, oil is oxidized by heat and oxygen of an electric field for a long time. Oils added with antioxidants and metal deactivators have better oxidation stability.

-

Dielectric loss reflects the degree of dielectric loss of oil products under an AC electric field. It is generally expressed as the tangent (tanδ) of the dielectric loss angle (δ). Generally, the dielectric loss of transformer oil measured at 90°C should be less than 0.5%.

Naphthenic oil is a good material for manufacturing electrical appliance oil due to its low pour point, good fluidity at low temperature, good electrical performance, good thermal stability and good thermal conductivity.

In the actual production process, due to the influence of external conditions, insulating oil will be inevitably contaminated by air, moisture and impurities. Various properties of insulating oil have been changed to cause the insulating oil to lose its use value. Faced with rising oil prices, energy saving and emission reduction have passed the necessity of modern industrial development. As a result, the oil filtration and oil recycling industry came into being.

As for the insulating oil, the treatment by the oil filter machine is completely reusable. According to the different requirements of customers, different types of insulating oil filtration machines can be used for processing.

-

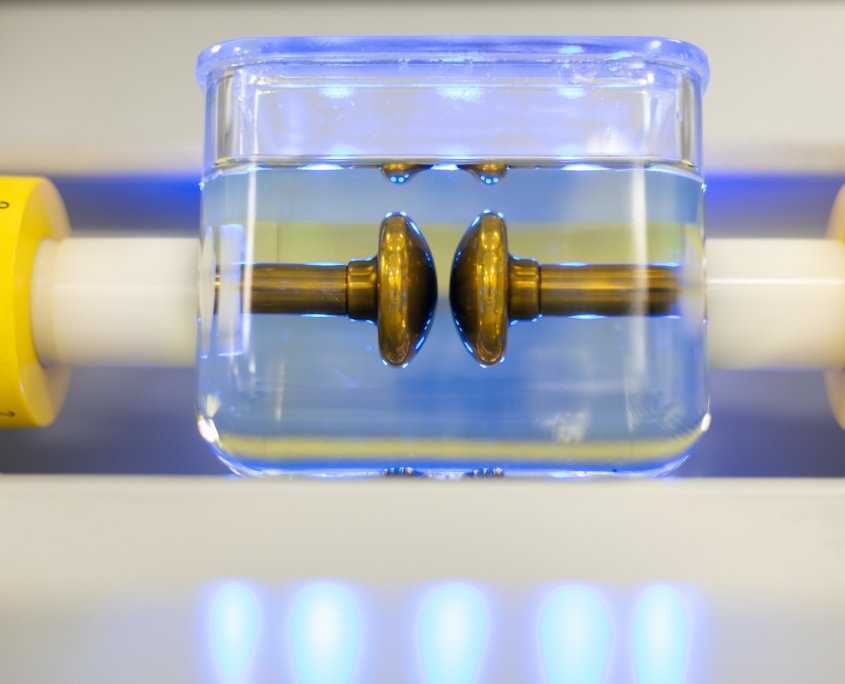

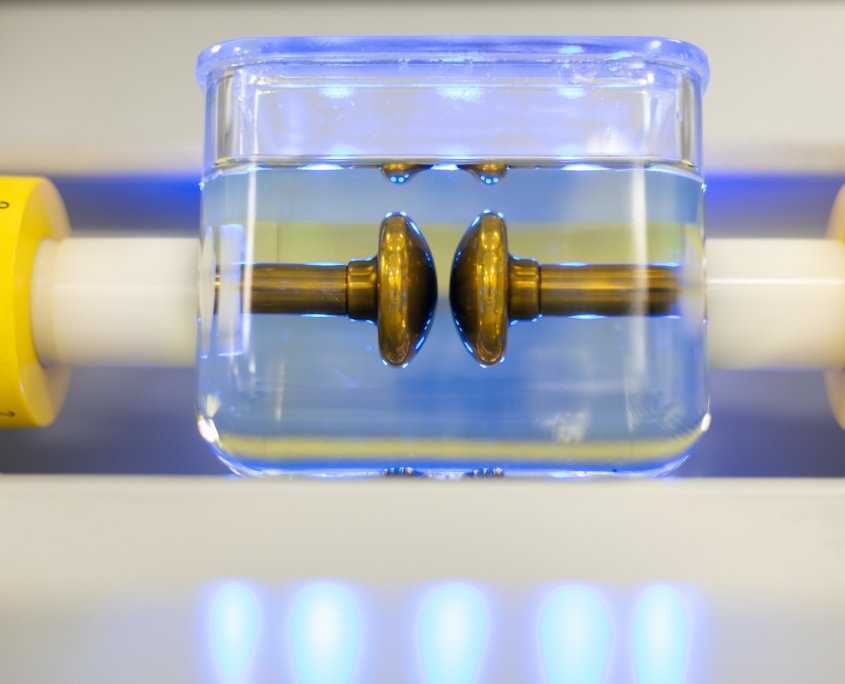

Vacuum Oil Purifier (Thermal Vacuum Oil Dehydrator). For the power sector, transformer manufacturers, etc., the requirements for insulating oil are very high, and the amount of insulating oil is also very large. Each oil change is a new investment for them. So a thermal vacuum insulating oil filter machine brought them a lot of cost-saving. Moreover, purchasing a Vacuum Oil Purifier is really cost-effective when comparing to changing new insulating oil. With the vacuum oil filter machine, you can filtrate, dehydrate and degas the transformer oil, as well as regenerate the used transformer oil, such as removal of acids, oxides and sludge. After oil purification, the breakdown voltage and dielectric strength will be dramatically improved, to meet the standards of reuse.

-

Portable Oil Filter Carts. Generally speaking, common oil filters on the market include plate and frame oil filters and oil filter carts. These two oil filters are mainly used to deal with impurities in insulating oil and separation of oil and impurities. The removal of impurities is mainly due to the fact that some customers have only impurities in their oil, or that the customers do not have high requirements for the performance of variable insulating oils, so ordinary oil filters with reasonable prices are accepted by the majority of customers.

You are welcome to inquire us about the processing proposals of your lubricating oils.

PureTech

Email: sales@cqpuretech.com | cqpuretech@gmail.com

Mob & Whatsapp: +86 17815389416