The main insulating material of the transformer includes following:

(a) Liquid insulating material - transformer oil

(b) Gas insulation material - air, SF6 gas for GIS side of high voltage bushing

(c) Solid insulating materials - insulating paper, insulating paperboard and paper products, wood and wood products

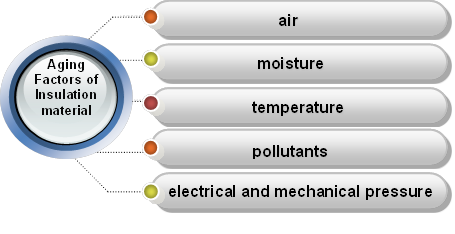

Ageing factors of transformer oil and insulating paper:

Main ageing factors of transformer insulation materials are: air, moisture, temperature, pollutants, electrical and mechanical pressure.

|

|

|

|

|

|

|

|

The main factors affecting the ageing of transformer oil are: temperature, moisture, oxygen and acidity.

Transformer oil will dissolve a certain amount of oxygen during storage and use. Under the catalysis of heat and metal, the oil will be gradually oxidized into various oxygen-containing compounds, and the deeply oxidized oil will appear gum and sludge. Oxides reduce the interfacial tension of transformer oil, increase the acid value and dielectric loss, and reduce the heat dissipation performance.

Oil that has been in operation for a long time will produce sludge under the condition of high temperature and oxygen, which will increase the dielectric loss of the oil and decrease the breakdown voltage. Heat dissipation drops. How to solve this problem?

According to the condition of transformer oil, we can selectively carry out oil degassing and dehydration and oil regeneration treatment on transformer oil. (Know more about Transformer Oil Purification and regeneration, please contact us or visit our products details)

The corresponding measures to be taken for the increase of oil dielectric loss factor are as follows:

a) The dielectric loss of transformer oil caused by high moisture content exceeds the standard. Vacuum oil filter can be used to heat the transformer oil to remove moisture to reduce the dielectric loss of transformer oil. The 500KV main transformer in our factory is generally degassed and dehydrated for 48 hours, and then it is drained for 48 hours;

b) Oil adsorption treatment, common adsorbents are white clay, aluminum oxide or fine-pored silica gel. Timely sampling test during the adsorption process, if the filtered oil is qualified, the work can be finished, and too deep fine filtration will also affect the oil quality;

c) Transformer oil with excessive dielectric loss can also be replaced by transformer oil.

d) In the specified operation transformer oil

Water-soluble acid (PH value)≥4.2; acid value/(mgKOH/g)≤0.1

The water-soluble acid in the transformer oil can be removed through the oil regeneration equipment and the adsorption of the adsorbent to reduce the acid value.

Oil treatment is a job that needs to be done basically every overhaul, because nuclear power transformers have the characteristics of long running time and strong load capacity, if the degassing, dehydration or adsorption of oil is not carried out under the window of power outage maintenance, the characteristics of continuous operation The gas is likely to exceed the standard, which not only increases the loss of the transformer and reduces the insulation performance, but also brings difficulties to our correct judgment.

The test proves:

The moisture content of the insulating part is 4%, and the service life of the transformer with an operating temperature of 90 degrees is 1 year;

The moisture content of the insulation is 2%, and the service life of the transformer with an operating temperature of 70 degrees is 30 years.

How to reduce the killer - the impact of moisture?

Necessary drying methods (dry air generator, transformer evacuation unit), oil degassing and dehydration treatment for overhaul (Transformer Oil Purifier, Transformer Oil Filtration Machine, Transformer Oil Regeneration plant, etc.), opening operation to shorten operation time, good sealing, no negative pressure area, how to carry out overhaul operation in high humidity environment in rainy season, etc.

Through the above example, we already know the importance of moisture and temperature on the life of the transformer. There are many factors to control the temperature, such as reducing the dielectric loss of transformer oil, reasonable transformer cooling method, no multi-point grounding of iron core, no short circuit between turns, short circuit between cakes, no local hot spots, good oil circulation, and no blockage of oil passages and many more.

In short, reasonable and effective control of the four factors that affect our transformers - water, temperature, oxygen and acidity will prolong the life of our transformers, otherwise it will greatly shorten the service life of transformers.

The transformer oil treatment equipment designed and manufactured by PureTech can meet the needs of different voltage levels of transformer oil treatment, such as 110KV and above high-voltage transformers, we recommend using a two-stage vacuum Transformer Oil Filter machine, which can achieve efficient treatment, and the treated transformer oil Reach the dielectric strength of 75KV and above, and the water content is less than 5PPM.

How to choose your Transformer Oil Filtration Machine ? Please click here.

Dears,

Through the above description, perhaps you already have a certain understanding of PURETECH's Transformer Oil Purifiers/Transformer Oil Filtration Machine/Transformer Oil Purifying Machine/Transformer Oil Treatment Plant. If you have determined the model, flow, power supply, configuration, etc. you need, please inform our sales team. We will prepare a quotation and detailed technical information for you as soon as possible for your further reference.

Web: www.cqpuretech.com

Email: sales@cqpuretech.com | cqpuretech@gmail.com

Tel: +86 17815389416 (WhatsApp)

Name: PURETECH

Mobile:+86 17815389416

Tel:+86 17815389416

Whatsapp:+8617815389416

Email:sales@cqpuretech.com

Add:1 Xinmao Road, Beibei district, Chongqing, China