High efficient and effective adsorbents such as fuller's earth, silica gel, sulfur acid, etc. are used for Transformer Oil Regeneration, filtration, purification and acid treatment. Today, we will talk about some common adsorbents or methods used for Transformer Oil Regeneration.

1. Fuller’s Earth

(a) Structural formula:

(b) Specifications:

The particle size is 90%~95% of 200 mesh through;

Decolorization power>125; activity>195;

Moisture≤10%; free acid below 0.2%.

(c) Physical and chemical properties:

White or off-white powder with a greasy feel.

Strong adsorption capacity, can absorb water, oil and certain gases.

Strong decolorizing power and good filtering performance.

Average chemical composition: SiO2 72%, Al2O3 14.5%, Fe2O33%, MgO 2%,CaO 0.8%, burning reduction 7.5%.

PureTech DVOP-R Transformer Oil Regeneration Plant with adsorbent

2. Silica Gel (or called acid-removing silica gel)

It is a highly active, regenerable adsorbent, artificial silica condensed from silica sol, with a large inner surface porous structure, hard particles and relatively stable chemical properties and high thermal stability. Its quality indicators are:

Moisture absorption rate≥72%; Mechanical strength>95%;

pH≤8.5; moisture <3%.

Density 400 ~ 500g/L;

Particle size ≥95% (2~4m/m and 4~8m/m).

In addition, the quality standard of spherical color-changing silica gel:

Moisture ≤4%; particle size above 2m/m.

Moisture absorption rate (at 100% relative humidity) ≥31%.

3. Sulfuric Acid

Concentrated sulfuric acid has strong water absorption, and the specifications of industrial sulfuric acid include three kinds of purity not less than 98%, 92.5% and 75%, and industrial sulfuric acid with a purity of 98% for oil regeneration.

4. Alkali (Caustic Soda)

Sodium hydroxide for oil regeneration, also known as "caustic soda", "caustic soda" or "caustic soda", is a white solid that easily absorbs water, and its aqueous solution is strongly alkaline. Generally, industrial caustic soda is used.

5. Antioxidant Alkyl Phenol

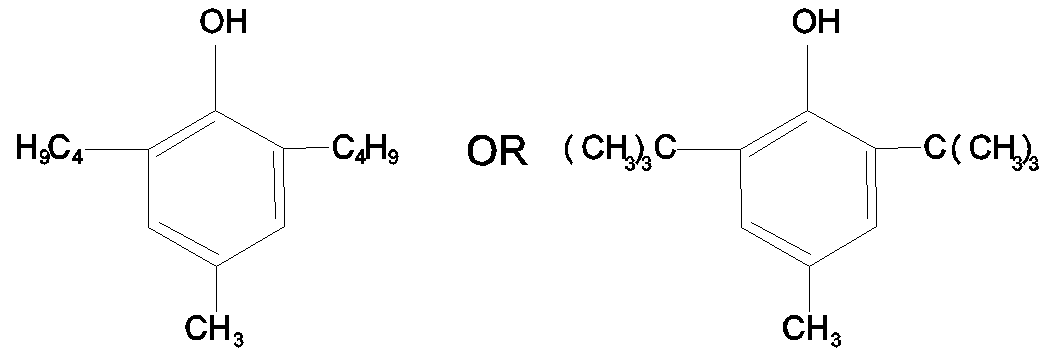

Chemical name: 2, 6-di-tert-butyl-4 (or p-)-methylphenol

Molecular formula: C15H24O

Structural formula:

Molecular weight: 220.19

Properties: White or slightly yellow crystals, insoluble in water and caustic.

Specification:

|

Index name |

First-class product |

Second-class product |

|

Appearance |

White crystal |

White crystal |

|

Melting point (℃) |

≥69 |

≥68.5 |

|

Moisture (%) |

≤0.06 |

|

|

Ash (%) |

≤0.01 |

≤0.03 |

|

Free acid (%) |

≤0.02 |

≤0.04 |

6. Oil filter paper:

The oil filter paper is divided into three types: fast, medium and slow. Fast filtration is faster, that is, the air permeability is larger, and the bursting resistance is lower. Slow, the filtering speed is slower. That is, the air permeability is lower, and the corresponding bursting resistance is higher. Intermediate speed between the two. Generally use medium speed filter paper, its quality standard:

Quantitative: (270±5) g/m2;

Air permeability: >400mL/min;

Thickness: 0.65~0.73m/m;

High water absorption: >80mm/10min;

pH: neutral;

Bursting strength: >2.7 kg/cm2

Our plate and frame oil filter cart adopts oil filter paper as its filter media.

Would you like to get our latest catalogue and price of Vacuum Transformer Oil Regeneration Plant ? Please contact us now.

We PureTech also specialized in transformer oil filtration, Transformer Oil Dehydration, transformer oil degassing, transformer oil polishing, transformer evacuation, etc.

Email: sales@cqpuretech.com

Tel: +8617815389416 (whatsapp)

Web: www.cqpuretech.com

Name: PURETECH

Mobile:+86 17815389416

Tel:+86 17815389416

Whatsapp:+8617815389416

Email:sales@cqpuretech.com

Add:1 Xinmao Road, Beibei district, Chongqing, China