Generally, for power transformers below 80 tons:

Suggestion: generally transport with transformer oil, and fill the space above the oil level in the tank with dry air;

And for power transformer of 80 tons and above:

Suggestion: transport without transformer oil and filled with dry gas (air or nitrogen) to keep the body and insulation dry;

(PureTech manufactures Dry Air Generator or called as Air Dryer Machine, please contact us for more information.)

PureTech Transformer Dry Air Generator

For transport of air-filled transformers, positive pressure is maintained in the oil tank, and the pressure is 0.01~0.03Mpa;

Before the transformer is transported, the comparative test of the change of the transformer transportation mode and unloading at the user's platform must be done first. These tests and inspections must include the following:

(a) Insulation resistance of iron core to ground.

(b) If possible, carry out the water content (ppm) and Dielectric strength/Breakdown voltage (kV) tests of the transformer oil in transit.

(c) If possible, check the reading value on the pressure gauge.

For transformers filled with dry gas for transportation, it is necessary to monitor the vacuum/pressure and temperature of the gauge. It needs to be checked frequently during transportation. Leakage will endanger the safety of transformer coils and insulation. Pressure and temperature values must be recorded and compared with factory values. For transformers shipped with positive voltage, the meter readings will appear negative when the ambient temperature is much lower than when it was shipped from the factory. In the worst case, the meter will read zero, which may indicate a leak. A dew point test must be performed at zero pressure or when the pressure/temperature relationship is in conflict with the factory one. The gas moisture content of the dew point test should be compared with the factory inspection value.

The internal parts of the transformer must be free from pollution and dry, so as not to affect the installation and operation of the transformer. These rules in the manufacture and transportation of transformers must also be followed during installation.

The transformer should not be opened in severe cold weather or in conditions that may cause condensation on the inner surface of the transformer and the external environmental conditions are not met.

During the normal installation of the transformer, it is best to prevent people or tools from entering the transformer oil tank.

It is strictly forbidden to enter the transformer with dirty or wet clothes. Clean cloth or nitrile shoes should be worn.

All tools, equipment and materials brought into the transformer should be listed for inspection and verification when they come out. Tools must have a hard surface to prevent chipping during use and must not have paint or plating on the surface. It is best to polish or blacken the surface of the tool. In order to prevent accidental falling off during use, the detachable part of all tools must be riveted on both sides, and the movable part must be piled to block or the threaded end must be welded firmly. Tools such as hammers and screwdrivers must have one end, and the handle is preferably cast in plastic or fiberglass. If the handle is wooden, it must be clamped with a wooden or plastic wedge. Nameplates or labels on tools must be removed. If you need to use a nameplate to distinguish it, you must use a non-metallic one, or wrap the nameplate with insulating tape.

When the transformer is on, never allow access to the transformer without clearing all pockets, checking for loose items, and removing watches, necklaces, etc. When opening the transformer and entering it for operation, it must be ventilated with dry air. The dew point of the dry air used must be below -40°C and be sufficient to maintain the air circulation of the operators in the tank.

Unless the oxygen content of the air inside the transformer exceeds 19.5%, it is not allowed to enter the transformer or breathe the gas in the transformer. Oxygen levels below 19.5% can cause coma, injury or death. It is not safe to enter a transformer with gas in it for transport. Oxygen levels should be checked frequently.

Be careful

To prevent contamination of the transformer, only manholes and openings in mounting parts may be opened. All other openings used must be covered with dry wood or clean plastic. This also minimizes dry air loss.

When injecting dry air into the transformer, sufficient air volume must be ensured so that the air flow can flow out from the opening of the transformer oil tank without interruption.

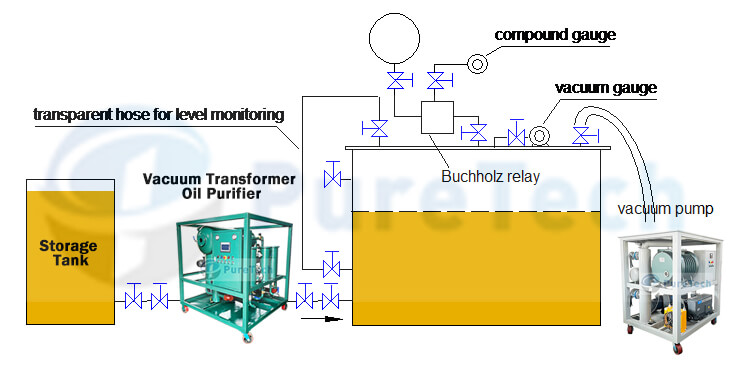

For installation of power transformers, vacuum Transformer Oil Purifier with following features is needed.

PureTech Transformer Oil Purifier Machine

High Vacuum Oil Purifier with constant oil temperature control (temperature controller). The oil filtration machine must meet the following requirements:

1) It can reduce the moisture contained in the oil, so that the moisture content is not higher than 10ppm (at 50 to 80°C), and the gas content after degassing should not exceed 0.5% (when the tank top is filled with oil), or not exceed 0.2% (when filling oil at the bottom of the tank).

2) The transformer oil purifier machine can filter out particles above 5µm.

3) The oil injection speed of the transformer oil filtration machine should not be lower than 2000 liters/hour.

4) The temperature of the oil outlet of oil purifier machine can reach 50-80°C.

5) The dielectrical strength of the purified transformer oil reaches:

60 kV/2.5mm method see IEC 156

60 KV/2.5mm method see GB2536-1990

6) The vacuum pump has sufficient capacity (for large and medium-sized transformers, 250m3/hour or 150 cubic feet/hour) to pump the oil tank to a residual pressure below 0.1kPa (about 0.75Torr); or as far as possible to 0.03kPa (about 0.2Torr).

7) The measuring range of the vacuum gauge is to cover 0.02~1kPa (0.15~7.5Torr). If a mercury vacuum gauge is used, a mercury trap must be used to prevent mercury from entering the transformer.

8) Vacuum-resistant and oil-resistant hoses, valves and pipe fittings connected to the transformer oil tank, transformer oil purifier machine, and oil tank, and oil purifier machine valves used on the oil tank (see the outline drawing of the transformer).

9) A transparent, vacuum-resistant plastic tube is used to indicate the oil level gauge when connecting the instrument and filling oil.

10) Oil tank (with desiccant respirator).

PureTech manufactures and supplys

(1) Double-Stage High Vacuum Transformer Oil Purifier (Transformer Oil Filtration Machine)

(2) Single-Stage Vacuum Transformer Oil Purifier

(3) Transformer Oil Regeneration Equipment

(4) Dry Air Generator / Air Drying Machine

(5) Vacuum Pumping System (Transformer Evacuation System, Vacuum Pump Machine, Transformer Vacuum Machine)

(6) Portable Oil Filter Unit

(7) Oil Test Instruments (Moisture Content Tester, Breakdown Voltage Tester)

More information of our products please feel free to contact us PureTech team. We will prepare a quotation and detailed technical information for you as soon as possible for your further reference.

Web: www.cqpuretech.com

Email: sales@cqpuretech.com | cqpuretech@gmail.com

Tel: +86 17815389416 (WhatsApp)

Name: PURETECH

Mobile:+86 17815389416

Tel:+86 17815389416

Whatsapp:+8617815389416

Email:sales@cqpuretech.com

Add:1 Xinmao Road, Beibei district, Chongqing, China