For the needs to remove trace moisture, gas

and impurities from transformer oil, turbine oil and other lubrication oils,

the vacuum oil filtration machine is the ideal equipment. Compared with

centrifuge separator, pressure oil filters (oil filter press) or portable oil

filter carts, vacuum oil purifiers have their unique advantages. First of all,

compared to centrifuge separator, vacuum Oil Purification Machines can remove

trace amounts of water and gas, while centrifuges are mainly used to remove a

large amount of water and large particles of impurities in the oil, so it is

not suitable for transformer oil and other oil which has a higher requirements

on low water content and other oil characteristics; in addition, centrifugal

oil separator cannot process the emulsified oil, and the vacuum oil purification

machine can demulsify and effectively separate oil and water. Second, for the

pressure oil filter and the portable oil filter cart, they can only remove the

impurities in the oil, but not the water and gas in the oil.

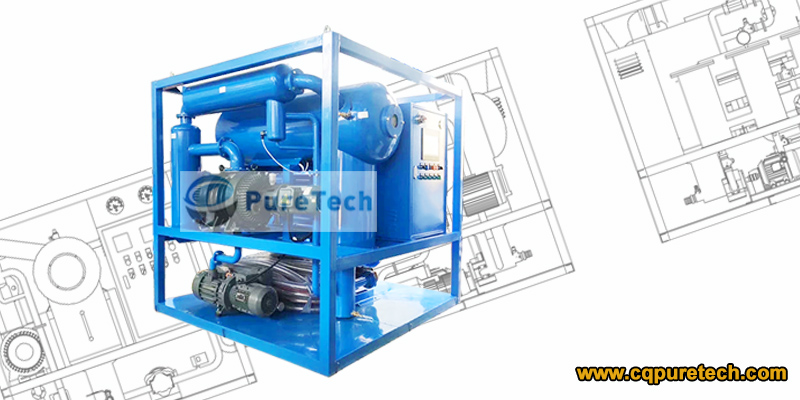

Therefore, for most of the current lubricating oil processing, the vacuum oil purifier can be competent. The main structure of the vacuum Oil Purification Machines generally includes the following parts:

PureTech vacuum dehydration and degassing system adopts the leading technology worldwide. In this system, the insulating oil is fully thinned (increase the exposure area of the insulating oil under the vacuum), and greatly increase the exposure time of the insulating oil in the vacuum system, so that the moisture and gas in the oil can be obtained enough vaporization time to achieve the best dehydration and degassing effect. The water content and gas content in the oil can quickly reach the standard of use. The vacuum system is equipped with an automatic foam detection and elimination device to effectively prevent oil foam from entering the vacuum pump and form a phenomenon of "oil running", therefore extending the service life of the vacuum pump.

PureTech's oil pump has the characteristics of uniform flow, no pulsation, and high efficiency; its structure is simple, compact, small in size, and light in weight; smooth operation, no vibration, low noise, and high reliability; good self-priming ability and tightness Good; long service life, maintenance-free features.

The sophisticated multi-stage filtration system, the filter material is encrypted step by step, the dirt holding capacity is large, the filtration precision is high, and the mechanical impurities in the oil can be effectively removed. Using Chinese or international well-known brand filter elements, high filtration accuracy (β≥1000), corrosion resistance, good mechanical strength, long service life, this filter element continuously filters 4000 tons of oil without any cleaning or replacement work, and has other The filter element has incomparable superiority and safety.

PureTech's vacuum oil filter electromechanical heating system adopts a unique design process, which has the characteristics of fast heating, stable oil temperature, uniform heating, no dead oil zone, and ultra-low heating surface load (≤1.5W/cm2). Ensure that the oil flows evenly across the heating surface, and there is no dead oil zone in the heater. A constant temperature controller (thermostat) is installed to ensure that the oil will not locally overheat during the heating process and cause the oil to crack.

The electrical control system is designed according to IEC standards. The main electrical components can be selected from French Schneider SCHNEIDER products, which are reliable in quality and stable in performance to ensure continuous operation of the equipment.

Set up a safety protection system with a high degree of automation, using advanced pressure protection devices, automatic defoaming, and automatic oil level control. Avoid the influence of misoperation on the equipment. During use, when the motor is overloaded, over-current, lacking phase, the filter element is blocked, the pressure increases, or the wrong operation, the power will be automatically disconnected to ensure the safe operation of the equipment, and the pollution degree of the filter material can be detected.

The highly sensitive liquid level control

system can automatically control the oil level of the degassing tank, making

the operation simple and the performance safe and reliable. Really achieve the

ideal working state of separation of man and machine.

Designed according to ergonomics

requirements, all components are placed and accurately positioned within the

reach of people. The filter element structure adopts a quick-change structure,

which is convenient for customers to replace the filter element. Maximize

production efficiency and reduce work intensity.

Currently, the vacuum oil filtration

machines developed by PureTech mainly includes the following:

a) Double-Stage High Vacuum Transformer Oil

Purifier

b) Single-Stage Vacuum Transformer Oil

Purifier

c) Double-Stage High Vacuum Transformer Oil

Regeneration Plant

a) Vacuum Lubrication Oil Purifier

(Universal Type)

c) Vacuum Hydraulic Oil Purifier

Welcome to consult us for the

recommendation of the suitable model for you. | www.cqpuretech.com | sales@cqpuretech.com

Name: PURETECH

Mobile:+86 17815389416

Tel:+86 17815389416

Whatsapp:+8617815389416

Email:sales@cqpuretech.com

Add:1 Xinmao Road, Beibei district, Chongqing, China