What is the significance of measuring the interfacial tension of insulating oil?

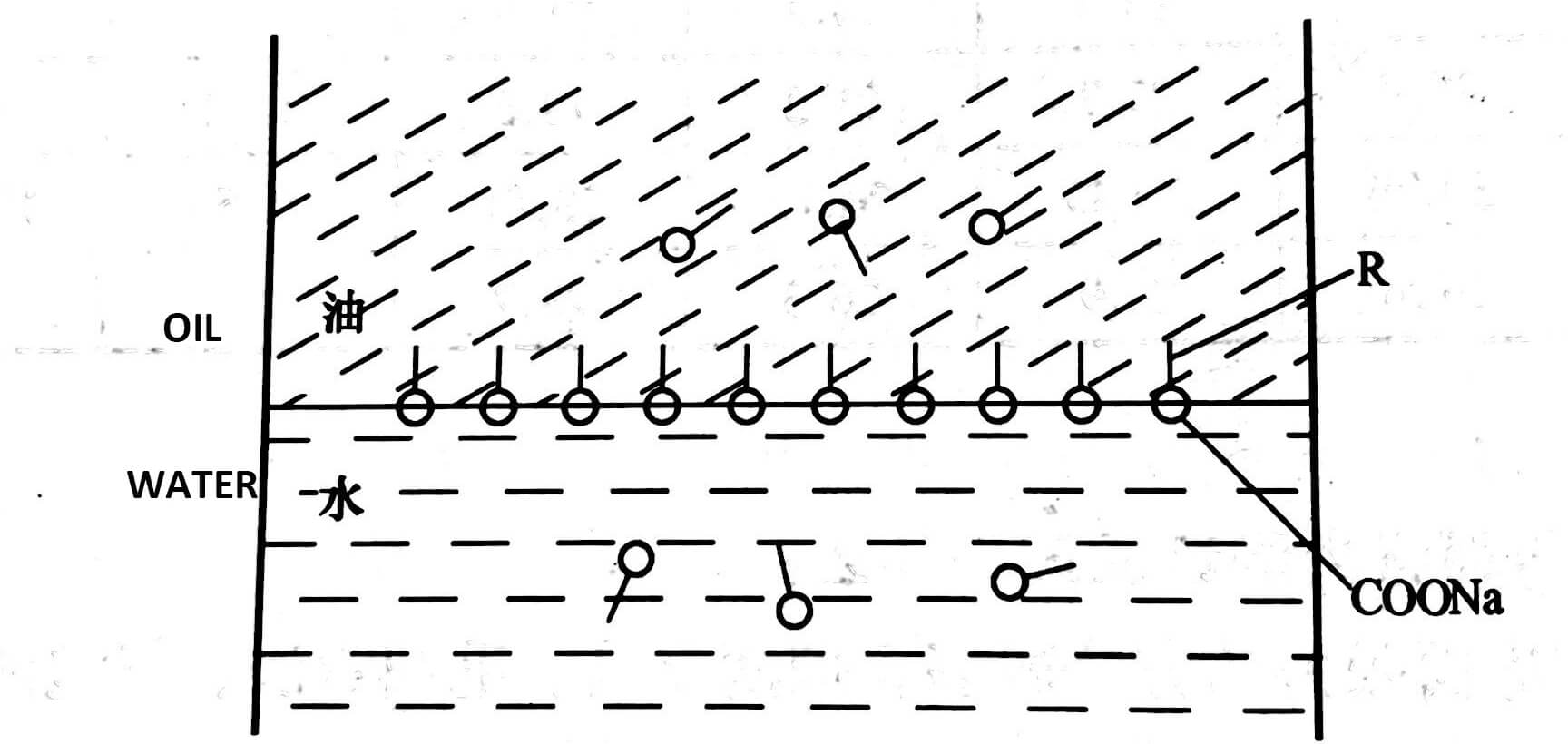

Let's talk about surfactants first. For a solution, its surface properties are different from those of a pure solution. The difference is that the composition of the surface layer of the solution is slightly different from the composition of the inner layer of the solution, that is, the concentration of the solute in the surface layer and the inner layer is different, and the surface tension of the solution is different. There is a significant relationship with the composition of the surface layer. Therefore, when a substance is dissolved in a liquid, the surface tension of the liquid changes. Practice has proved that some substances can reduce the surface tension of liquids. People call all substances that can reduce the surface tension of solvents as surface active substances. Such as fatty acid R-COOH, alcohol R-OH and other substances, in addition to containing polar groups, there is a sufficiently long non-polar part (such as carbon chain), polar groups are hydrophilic, non-polar groups are hydrophobic Yes, if at the interface of the two phases with different polarities, these surface active substances will be aligned, the polarity is towards the polar, and the non-polar is towards the non-polar (as shown in the figure below). This arrangement changes the original molecular arrangement and reduces the interfacial tension.

(Surface-active substances are aligned at the oil/water interface)

Insulating oil (used as transformer oil) is a mixture of various hydrocarbons, except for some alkanes and a small amount of aromatic hydrocarbons, the main component is naphthenic hydrocarbons. Under the influence of temperature, oxygen, light, catalyst, water, pollution, electric field, etc., the transformer oil in operation makes the chemical structure change continuously. The deterioration deepens and the products increase. For example, the oxidation products of naphthenic hydrocarbons, alkanes or long-side chain less-cyclic aromatic hydrocarbons are mainly carboxylic acids, carboxylic acids and a small amount of condensates (resins). However, the oxidation products of aromatic hydrocarbons with short side chains (or aromatic hydrocarbons with long side chains after chain scission) contain less acidic substances and more sludge deposits. These polar (hydrophilic) molecules that exist in insulating oil due to oxidation or pollution, such as soaps, acids, etc., will gradually migrate from the oil body to the oil-water interface, condense on the oil/water interface, and end up in the form of carboxyl The acid groups are oriented towards the aqueous phase. This significant change in molecular distribution at the two-phase interface leads to a decrease in interfacial tension.

The change of oil/water interfacial tension of transformer oil can be measured in time to observe the change of oil quality. Therefore, the measurement of oil interfacial tension is of great significance to the actual operation of insulating oil and to evaluate the degree of deterioration of insulating oil, especially in the presence or absence of surface-active polar components and other impurities or mixtures. So it is one of the main indicators to characterize oil aging. Generally, the surface active substances in pure new oil are very small, and the interfacial tension of the oil is relatively large, which is (40~50) x 10-3N/m, or even more than 55 x 10-3N/m, while the interfacial tension of the aged oil decreases. It is stipulated that at 25°C, the oil before being put into operation should be >35 x 10-3N/m, and the operating oil should be >19 x 10-3N/m.

In addition, the test method is simple, requires less oil, and does not require chemicals, which provides convenience for on-site monitoring of oil quality, so the interfacial tension test is becoming more and more popular.

Secondly, the use of interfacial tension can also supervise the operation of the transformer thermosyphon. Generally speaking, if the thermosyphon is running normally, the adsorbent has not failed, and the pH value of the oil is greater than 4.6, the interfacial tension of the oil is about (30~40) x10-3N/m; if the thermosyphon fails and the pH value of the oil is lower than 4.6, the interfacial tension of the oil is about (25~30) x10-3N/m. If the interfacial tension of insulating oil (especially distribution transformer) during operation is lower than 20x 10-3N/m, sludge may be precipitated.

It should be noted that since the interfacial tension reflects the total amount of hydrophilic polar molecules in the oil, all additives belonging to this category can reduce the oil-water interfacial tension, such as adding a pour point depressant (polymethyl methacrylate) to insulating oil. Acrylate), etc., because it contains carboxyl group (-COOH), the interfacial tension of oil will change with its addition amount.

PureTech Oil Filtration designs and manufactures vacuum Transformer Oil Purifier, which can effectively removes moisture, gas and impurities from transformer oil, thereby improving the interfacial tension of transformer oil. After purification by PureTech DVOP model Double-Stage vacuum Transformer Oil Purifier, the interfacial tension of transformer oil can be improved to above 40mN/m, and water content to lower than 5 ppm, breakdown voltage to above 75kv.

More details of transformer oil purifier machines if you are interested, please contact us freely.

Name: PURETECH

Mobile:+86 17815389416

Tel:+86 17815389416

Whatsapp:+8617815389416

Email:sales@cqpuretech.com

Add:1 Xinmao Road, Beibei district, Chongqing, China