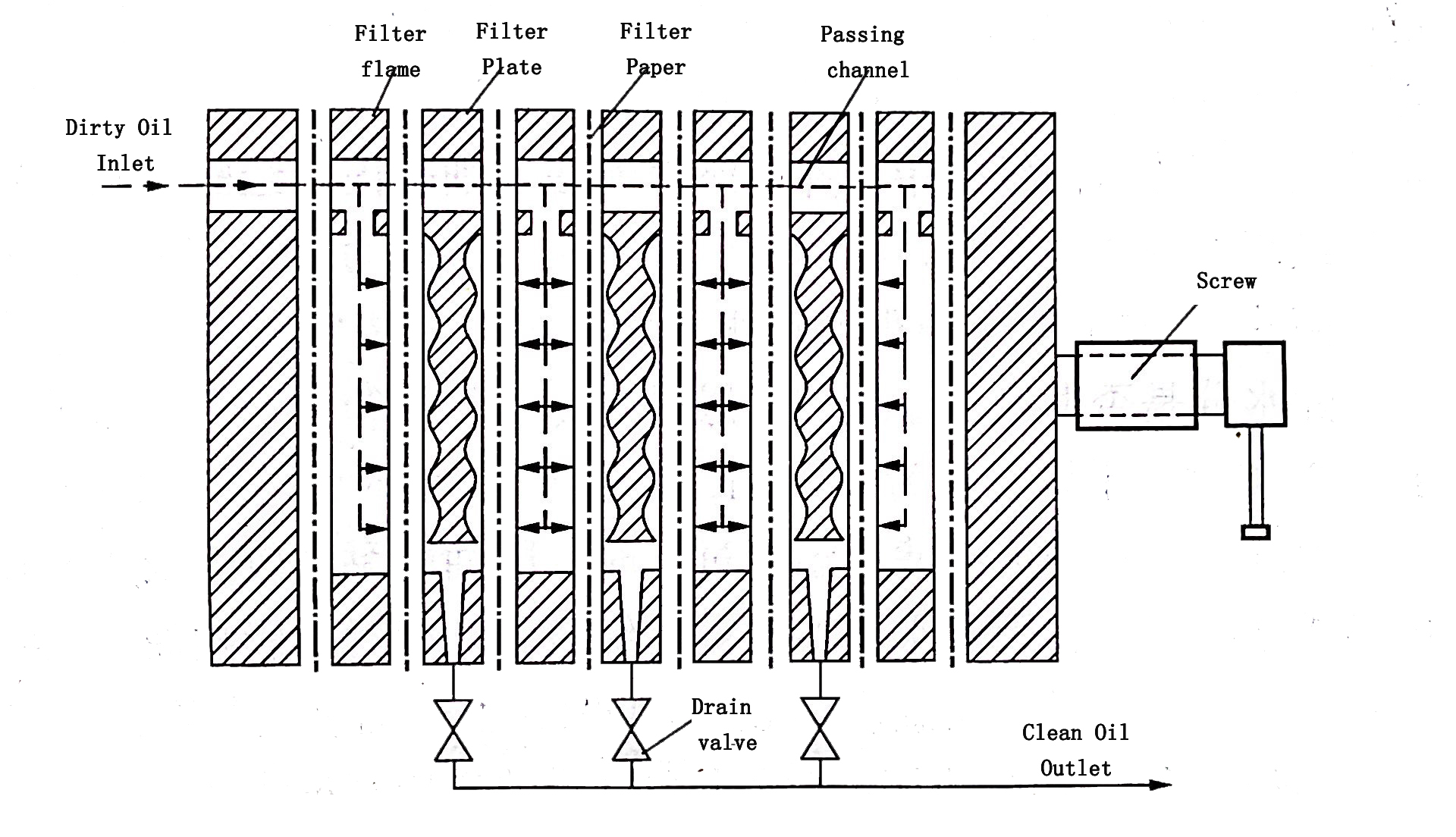

The pressure oil filter machine uses the oil pump to pass the oil with a certain pressure through the filter medium, that is, the pressure difference between the two sides of the filter medium is used to make the oil pass through the filter medium, and the impurities and moisture are blocked.

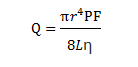

The filter medium not only includes filter paper or other filter media (such as filter cloth, silk, etc.) with adsorption and filtration functions, but also includes the precipitation layer retained on the filter material. Its filtering speed should obey the Poseli formula:

In the formula,

Q- filter speed;

P- filter pressure difference;

F- filter area;

η- absolute viscosity of oil at filtration temperature;

r- the radius of the capillary in the filter medium;

L - the length of the capillary in the filter medium. It is proportional to the thickness L1 of the filter medium, but the value is much larger than L1. Because the capillary is tortuous.

What are the factors that affect the effect of pressure filtration?

There are many factors that affect the effect of pressure filtration, and the filter medium is the key factor. In the actual process, the filter medium includes not only filter paper, but also a thin layer of sediment that is retained on the filter paper. With this thin layer of sediment, finer sediments (containing free carbon). The filter paper is generally made of industrial adsorption paper. Because of its loose fibrous structure, it forms a crisscrossed porous shape. When the pressure is not too high, 1.5 x 105~3x 105Pa, moisture may infiltrate into the pores of the filter paper, and always adhered to the pores. Experience shows that, in order to make the filter paper filter out water better, the best preheating temperature of oil is 35~45℃ (turbine oil can be higher). The degree of dryness of the filter paper is also critical, because it determines the efficiency of the oil filter and the completeness of the removal of water. The drying of the filter paper is carried out in a special oven. When the drying temperature is 80℃, the drying time is 8~16h, and when the temperature is 100℃, the drying time is 2~4h.

Temperature influence: When the temperature of the oil flowing through the filter paper is too low, due to the high viscosity of the oil and the formation of crystal lattices in the oil, the water is not easily absorbed by the filter paper, and also affects the filtration speed of the oil; when the temperature is too high, such as the temperature When the temperature reaches 80~100℃, due to the reduction of oil viscosity and the enhancement of water activity, under a certain pressure, water will pass through the filter paper without being adsorbed, and the filtration effect will also be reduced. Therefore, in order to ensure the filtration effect and the necessary filtration speed, it is generally best to control the temperature of the filtration oil at about 40 °C. If the filter is not heated indoors (except in winter, the room temperature is too low), the oil temperature can be appropriately increased in outdoor winter.

Pressure: The normal working pressure of the filter press is 1x105~4x105Pa (depending on the oil and temperature). During filtration, if the pressure gradually increases, even exceeding 5x105~6x 105Pa, it means that there are too many pollutants in the oil, filling the pores of the filter paper. At this time, fresh dry filter paper must be replaced (under the premise that the outlet pipe is unobstructed).

The thickness of the filter paper is usually 0.5~2.0mm. Since 2~4 pieces of filter paper (some are still one) are generally placed between the filter plate and the filter frame, when replacing the filter paper, it is best to start from the first one on both sides of the filter frame, and extract the filter paper at each layer. At the same time as one, you can put the new filter paper on the side close to the filter plate. Practice has proved that this replacement method not only saves filter paper, reduces fuel consumption, but also receives good filtering effect. After replacing the filter paper, during the initial filtration, the filtered oil may have more air bubbles, which is the reason why the gas in the pores of the filter paper is squeezed out by the oil. This is unfavorable, so it is not that the filter paper is replaced more frequently and more, the better, but it should be determined according to the pollution of the filter paper (see whether the outlet pressure increases or whether the filter paper becomes soft after absorbing water), this is scientific .

Name: PURETECH

Mobile:+86 17815389416

Tel:+86 17815389416

Whatsapp:+8617815389416

Email:sales@cqpuretech.com

Add:1 Xinmao Road, Beibei district, Chongqing, China