To ensure the safe and reliable operation

of steam turbine generator sets, the function of steam turbine oil is very

important. So it must have the performance that can meet the following aspects:

(1) The viscosity of the oil can be

maintained within the specified operating temperature range and the oil quality

is qualified.

(2) It can ensure that all lubricated parts

form a thin oil film, minimize friction, resist wear, and extend the safe

operating life of the equipment.

(3) Through the oil circulation, the heat

generated by the journals, bearings and other heat sources can be transferred

to the oil cooler for cooling through the oil.

(4) Because the lubricating oil runs under

non-sealed conditions, it must be able to resist oxidation and deterioration in

the presence of air, water, hydrogen and high temperature environments.

(5) It can inhibit the generation of

bubbles and entrained air.

(6) The water entering the lubrication

system can be separated quickly and discharged from the bottom of the oil tank.

(7) It is also necessary to protect the

quality of equipment components from corrosion and rust.

(1) Temperature. It has a great influence

on the oxidation reaction speed, and the reaction speed increases when the

temperature rises. Generally speaking, the influence is greater when the

temperature is above 60℃. At this time, the oxidation speed will double for every 10℃ increase,

that is, the oxidation speed at 70℃ is 60℃ At 80°C, it is

twice as high as at 70°C, which is 4 times as much as at 60°C. Lubricating oil

has a thermal load during operation. Different units and different operating

conditions (such as whether the unit is running at full load, etc.) produce

different heat, and the temperature rise of lubricating oil is also different

(that is, the thermal load is different), and the heat load is different. It

will be uniform, and there will often be local "hot spots" in the

lubrication system, which will accelerate the oxidation process of the oil and

cause thermal oxidative deterioration.

The oil will crack at high temperature,

forming unstable compounds, which will be further polymerized into various

resins and sludge. Above 100°C, the sludge will be carbonized to form a

coke-like mixture, which is more harmful.

(2) Contamination. Same as transformer oil degrades, moisture, metals and

particulate matter are very important contamination in turbine oil during the long term operation. Their presence will promote the deterioration of oil

quality and also contribute to the formation of foam, fouling and sludge. And

these impurities quickly enter the running turbine oil. In operation, the

turbine oil contains more or less impurities, so pay attention to timely

removal.

(3) The structure and design of the oil

system also affect the rate of deterioration of oil quality. Such as an oil

tank, it is not only a reservoir for all the oil in the lubrication system, but

also can separate the air, moisture and impurities in the oil from the oil

during the residence time in the tank. Therefore, the structural design of the

fuel tank (such as the size of the volume, the location of the components in

the tank, the flow route of the oil in the tank, etc.) has a certain influence

on the deterioration of the oil quality. For example, if the design of the fuel

tank volume is too small, the oil staying time in the tank will be reduced, the

number of cycles (same time) will be more, the precipitation of impurities from

the oil and the demulsification time of emulsified oil will be shortened, and

the result will be no separation or separation of air, moisture, etc. If the

separation is not good, a part of it will continue to circulate in the oil

again, which will accelerate the deterioration of the oil. Secondly, the oil

pressure and flow rate are also related to the deterioration of oil quality.

The oil in the oil inlet pipe should maintain a certain pressure and flow rate

(about 1.5~2m/s). There is no pressure on the oil in the oil return pipe, and

the oil flow rate must be small (about 0.5~-1.5m/s) to avoid splashing of oil

in the oil tank, forming foam, causing residual gas in the oil, and

accelerating the deterioration of oil quality; at the same time, the flow rate

is large, which may make the oil tank When the oil is stirred vigorously, the

water-containing oil may become emulsified and accelerate the deterioration of

oil quality.

(4) Radiation. This is mainly for nuclear

power plants. The degree to which the steam turbine oil in nuclear power plants

is affected by radiation depends on the composition and additives of the oil

itself. Alkanes and cycloalkanes are more affected than aromatic hydrocarbons.

After radiation, the C-C and C-H bonding bonds are split, and H2 can be released

at the same time. The release amount is less. As the composition changes, of

course the physical and chemical properties and lubricating properties of the

oil also change. The prominent reaction is: gas evolution, increased viscosity,

reduced corrosion resistance and oxidation stability, increased acid value,

darker color, sludge, unpleasant odor compounds, and decreased flash point. But

generally speaking, the above phenomenon will only occur when the radiation

dose is greater than 106J/kg.

(5) Internal factors: the chemical

composition of oil. It is a mixture of hydrocarbons. The relative proportions

of paraffinic diameter, naphthenic hydrocarbons and aromatic hydrocarbons in

the base oil are different, and the physical properties such as viscosity index

and pour point are also different; aromatic hydrocarbons affect the stability

of the oil and its structure and in the oil. The content is related, so when

new oil is generated, it is often taken to increase the depth of base oil

refining, reduce harmful substances in the oil, and add additives to improve

the quality of the oil. However, the compatibility of additives has a certain

effect on oil stability. Therefore, if the additives are not well selected, it

will be counterproductive and make the oil performance worse. Therefore, a

small test should be done before adding.

6) The quality of oil system maintenance is

not good, especially the pipelines of leaking units. There are often rust,

emulsion, sediments, etc. in the oil. If the maintenance cannot be completely

removed, the quality of the oil will definitely be reduced. For example, when

cleaning the pipeline, in addition to mechanical methods, cleaning agents such

as washing powder should be used, and more attention should be paid to

cleaning, and there should be no residual cleaning agent, otherwise it will

contaminate the oil and accelerate the deterioration of the oil.

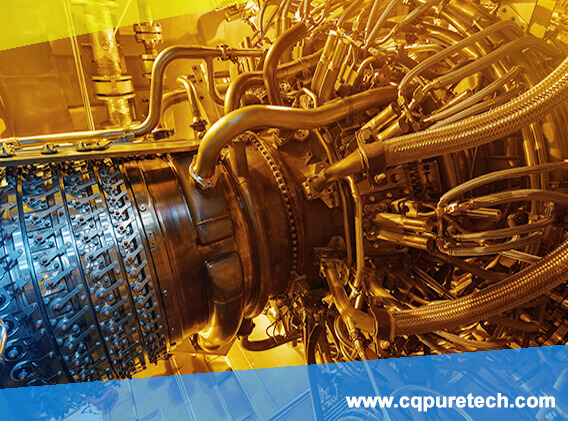

PureTech Oil Filtration provides you with following equipments which are suitable for turbine oil treatment:

And among above Turbine Oil Purifiers, the thermal-vacuum turbine oil purifier is most widely used in power generation companies. It can work online and perform 24 hour online oil cleaning service. What's more, with thermo-vacuum technology, the water content in turbine oil will be reduced to lower than 50 ppm after purification.

Welcome to contact PureTech Oil Filtration for more information about steam turbine oil filtration. And if you want to know transformer oil filtration or other oil filtration plants, please visit our website.

PureTech Oil Filtration | www.cqpuretech.com | sales@cqpuretech.com | +8617815389416

Name: PURETECH

Mobile:+86 17815389416

Tel:+86 17815389416

Whatsapp:+8617815389416

Email:sales@cqpuretech.com

Add:1 Xinmao Road, Beibei district, Chongqing, China