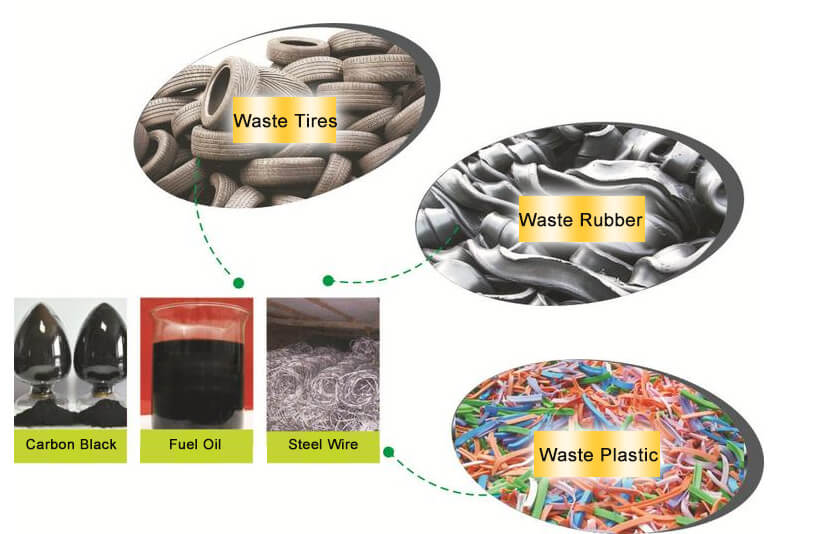

PureTech designed TOD series Continuous Tyre Pyrolysis Plant can perform a comprehensive treatment of waste rubber products and tires, and produce both carbon black and fuel oil at the same time. This not only solves the problem of discarding and pollution of waste tires and rubber products, but also produces usable energy and resources.

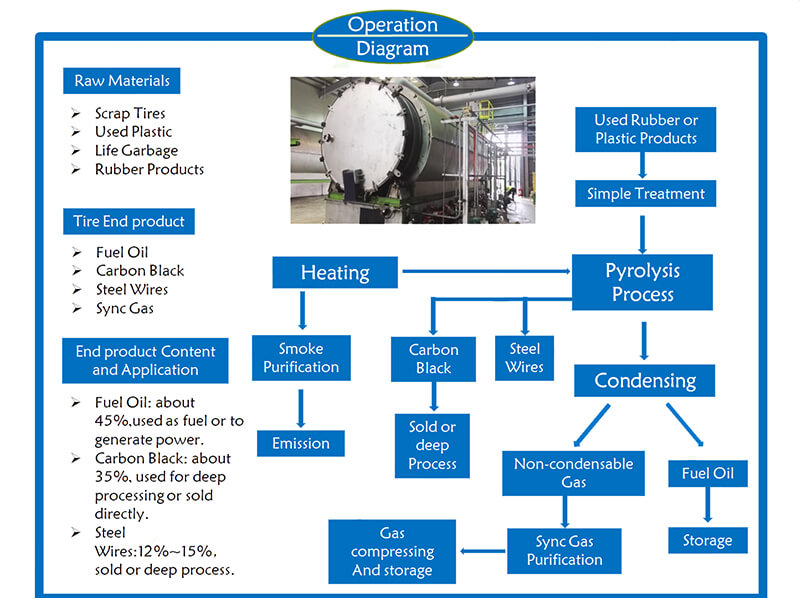

Using waste rubber as material, the tyre pyrolysis plant that attached with latest sealed thermal heating design, enables rubber molecule pyrolyze and parts of them are recombined into fuel.

When the whole rubber pyrolysis process is over, we can get three kinds of by-products. And they are rubber pyrolysis oil,carbon black and combustible gas. The followings are their applications:

1. Fuel oil: can be widely used in industries such as steel and iron and boiler factories, ceramics, power or chemical industries etc. It can also be used for power generators to get electricity.

2. Carbon black: can be mixed with clay and used for construction bricks, also can be used as fuel.

3. Combustible gas: can be recycled to heat the reactor as fuel, which will save energy for the whole working process.

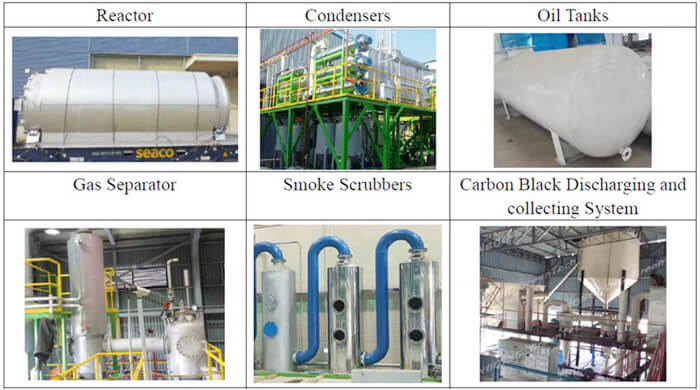

• Fully open door: convenient and fast loading, fast cooling, convenient and quick wire drawing;

• Thorough cooling of the condenser, high oil output rate, good oil quality, long service life, and easy cleaning;

• Original water mode desulfurization and dust removal: It can effectively remove acid gas and dust and meet the relevant national standards;

• Slag discharge from the center of the large furnace door: airtight, automatic slag discharge, clean and dust-free, and save time;

• Safety: automatic submerged arc welding technology, ultrasonic non-destructive testing , Manual and automatic safety devices;

• Exhaust gas recovery system: fully burned after recovery, save fuel and prevent pollution;

• Direct heating: special process, increase the heating area of the furnace body, rapid heating, easy control of temperature, and effectively extend the use of equipment Life;

• Unique thermal insulation shell design: excellent thermal insulation effect, good energy-saving effect.

Tire is mainly composed of rubber (include natural rubber and synthetic rubber), carbon black and many other organic and inorganic addition agents (include plasticizer, antiager, sulphur, zinc oxide, etc). Waste tire pyrolysis means the process that under a sealed furnace with proper heating, the main chain of the rubber in tires cracked into monomer, biopolymer and fragments, which then be polymerized to many kinds of olefins, thus get rid of the volatile substances to solid carbon. The main end products are fuel oil, pyrolysis gas, carbon black and steel wire. The composition of every product is different as different pyrolysis methods, temperature, etc.

Through tire pyrolysis process, it could recycle waste tires to renewable energy, also without generating secondary pollution to the environment. And PureTech' s new type waste tire pyrolysis plants are all equipped with smoke cleaning system, tail gas cleaning system, bad smell removal system and water circulation system, thus to keep no pollution to both the air and water.

The final products after the pyrolysis process of waste tires, waste plastics, and rubber products include: fuel oil, steel wire, carbon black, and combustible gas, and their uses are:

(1)Fuel oil: as a fuel used widely in industrial enterprises such as steel plants, ceramic factories, chemical enterprises, and engineering machinery, etc., and can also be used as fuel oil for power generation by heavy oil engines.

(2)Steel wire: Only waste tire pyrolysis can produce steel wire. The content in the tire is 12%-15%, which can be reprocessed.

(3)Carbon black: Coarse carbon black can be used as a raw material for building bricks, and can also be further processed into industrial carbon black, semi-reinforcing carbon black, color, plain carbon black, and has a wide range of applications.

(4)Combustible gas: The content is about 5%, which can be recycled and used in the production process as a fuel for production.

* Please inquire us about the technical specifications as per your desired capacity.

* Delivery date around 40~60 days, please confirm with us before placing order.

* This plant requires on-site installation and commissioning, please consult us.

• 12 months of quality guarantee for non-human damage.

• Lifelong maintenance and spare parts supply.

• Free training on operation, maintenance and troubleshooting at PureTech factory.

• Puretech engineers go to customer site for installation guide, commissioning and training (charge service).

• Design accept user's customization.