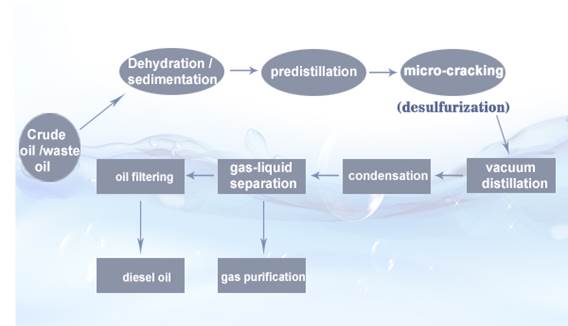

Model WOD Waste Lubricating Oil Distillation Plant, is widely applied in many industries to recycle and regenerate waste oils, such as engine oil, marine oil, machine oil, transformer oil, gear oil, lube oil, hydraulic oil, etc. By the means of distillation technology, high quality diesel fuel or base oil can be obtained from the waste oil with a high production rate.

• Can both produce the diesel oil and base oil according to your demands.

• Wide applications.The oil distillation machine can recycle all kinds of engine oil,

motor oil, lube oil, tire oil, pyrolysis oil, heavy fuel oil, gear oil, machine

oil etc. .

• Low cost, cost is 30$ for refine one tons used lube oil.

• Easy to operate,low operation cost, only 1-2 workers can control the machine.

• Environmental friendly, installed with the gas purification.

• High recovery rate.

• Efficient vacuum distillation systems.

• High quality refined oil, no any discoloration caused by oxidation.

PureTech-WOD Waste Lubricating Oil Distillation Plant adopts our exclusive patent Full-Bridge Rectification & Electromagnetic Eddy Current Heating technologies, combines with our unique Macromolecular Bubbling decoloration and Membrane Crystallization Separation patents. The entire plant applies the pure physical working principle, even heating and self-balancing flow, it has no damaging of oil substances.

| Item | WOD-5 |

WOD-10 |

WOD-15 |

| Production Capacity | 5 Ton/Day |

10 Ton/Day |

15 Ton/Day |

| Oil Inlet Flow | 50 L/M |

100 L/M |

200 L/M |

|

Average Power Consumption |

48 KwH |

135 KwH |

158 KwH |

|

Vacuum Degree |

≤ -0.06 ~ -0.09 MPa | ||

|

Oil Heating Temperature |

175℃-220℃ |

175℃-280℃ |

175℃-280℃ |

|

Power Supply |

220/380V, Or as per your local power supply |

||

|

Noise |

≤70dB |

||

* Please inquire us for other capacities or types.

* Delivery date around 40~60 days, please confirm with us before placing order.

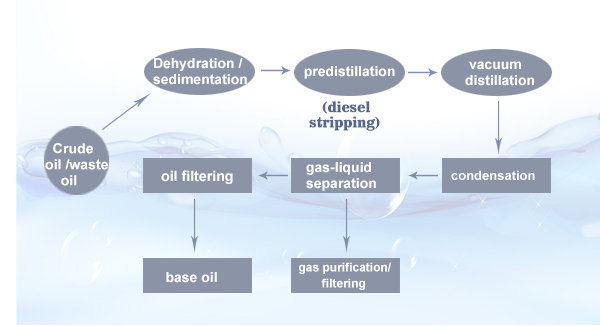

To produce base oil from WOD waste oil distillation plant:

• 12 months of quality guarantee for non-human damage.

• Lifelong maintenance and spare parts supply.

• Free training on operation, maintenance and troubleshooting at PureTech factory.

• Puretech engineers go to customer site for commissioning and training (payable service).

• Design accept user's customization.